OGP UK to exhibit at MACH 2024 | 15-19th April, NEC Birmingham Learn More >

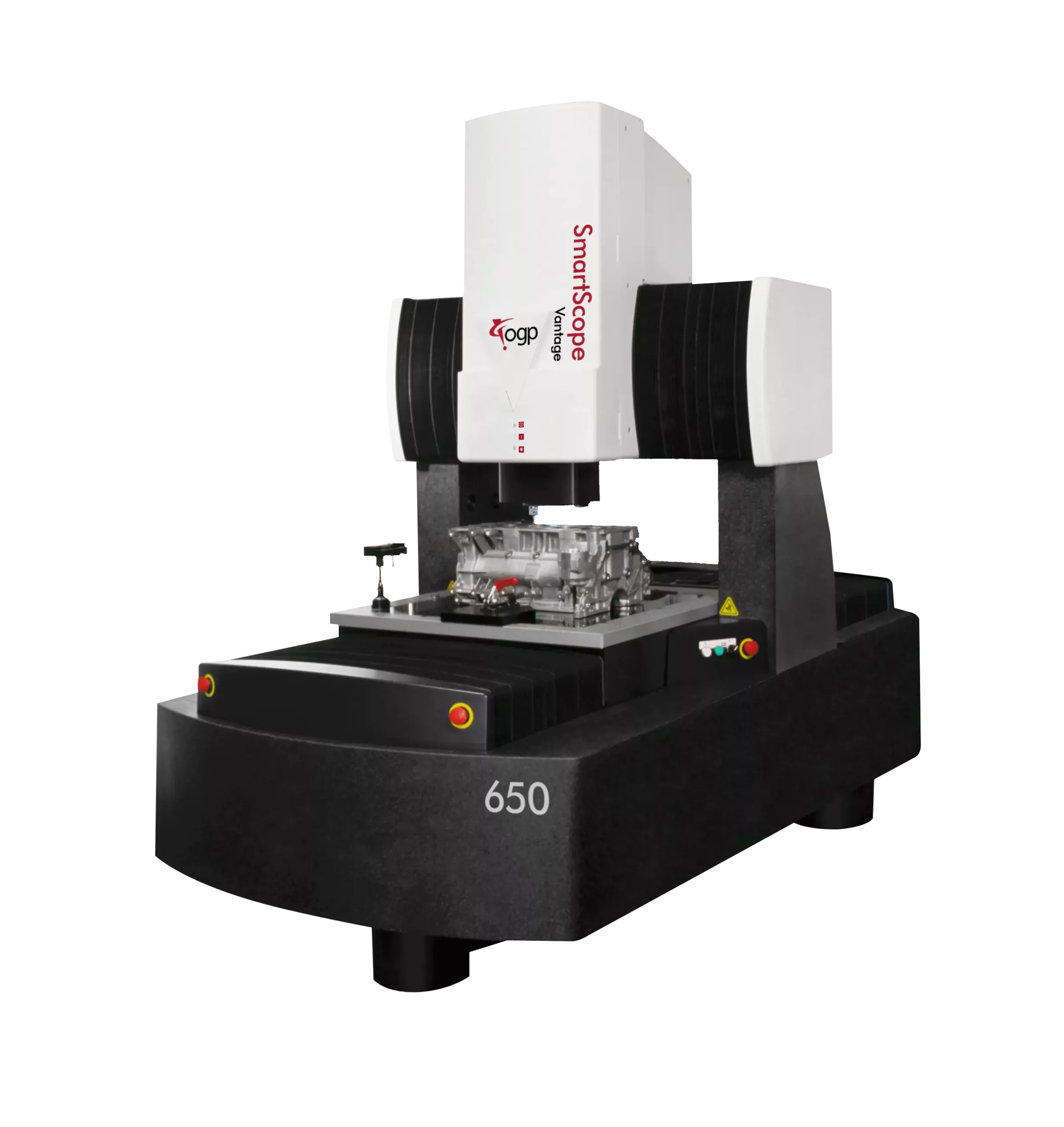

Multi-Sensor Measurement Systems

Discover accuracy, precision and industrial quality control with the full range of OGP measurement technologies.

Discover the power of

multi-sensor measurement

OGP UK provide fast and repeatable measurements at your fingertips with multi-sensor measurement systems designed to withstand the demands of everyday manufacturing. For 100% reliability in inspection, fast measurements of multiple parts in one cycle, and accuracy OGP provides confidence, when results matter.