Manufacturing technology is rapidly advancing, producing more complex parts faster, and machines often running even in unmanned hours. This siege of technology requires inspection equipment to keep up and find new solutions to ensure parts can be measured quickly, accurately, and consistently.

Shopfloor inspection is a critical component of quality control and assurance in manufacturing processes. Inspecting parts right where they are produced speeds up the inspection process and helps to ensure that the parts meet the specified quality standards, dimensions, and criteria.

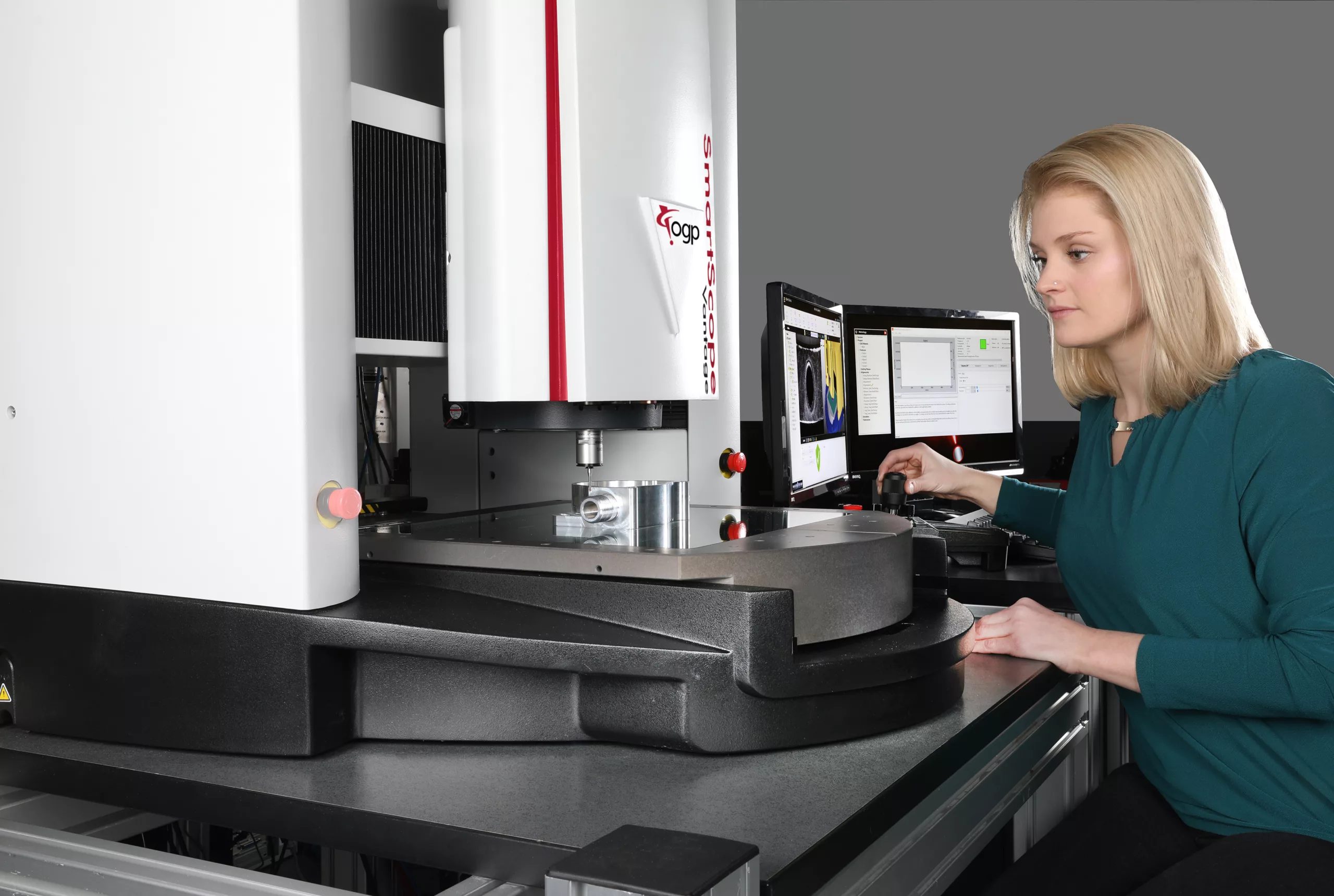

OGP UK provides best-in-class multi-sensor measurement systems combining optics, lasers, rotaries and probes for unrivalled performance in the quality control of manufactured parts and components. OGP UK metrology machines can function on the shopfloor, providing accurate and reliable measurements of parts and products in a variety of manufacturing environments. Their rugged and durable design can withstand the harshest shopfloor conditions, including; vibration, dust, and temperature changes.

Here are the top 10 reasons it is vital for modern manufacturing companies to measure their parts on the shopfloor …

1. Real-Time Quality Control

Shopfloor inspections allow for immediate detection and rectification of issues during the manufacturing process. This is crucial for maintaining product quality and preventing any defects or deviations from the original design and quality specifications.

2. Cost Efficiency

Detecting defects earlier within the manufacturing process is cost-effective as it allows for repairs and reworks before moving further down the production line, minimising scrap, rework, or product recalls.

3. Minimized Production Downtime

Identifying and addressing quality issues on the shopfloor minimizes downtime, ensuring that production lines continue to run smoothly and meet deadlines.

4. Ensure High-Quality Products

Measuring on the shopfloor ensures high-quality parts are produced consistently, enhancing the company’s reputation, and increasing their product standard.

5. Enhanced Process Efficiency and Optimisation

Regular inspections on the shop floor provide valuable insights into the manufacturing process. Analysing inspection data can lead to process improvements, efficiency optimisations, and the implementation of best practices, resulting in better overall enhanced productivity.

6. Compliance with Regulatory Standards

Many industries have strict regulatory requirements and quality standards that must be met. Inspecting parts on the shop floor ensures compliance with the strict regulatory requirements and quality standards of their clients.

7. Data-Driven Decision Making

Collecting data directly from the shopfloor allows for real-time data analysis and trend identification. This informs data driven decision-making, process adjustments, and improvement strategies based on factual evidence from the shopfloor.

8. Immediate Feedback to Operators:

Shopfloor inspections provide immediate feedback to operators and production staff, helping operators understand the quality expectations of the products and make real-time adjustments to the production process.

9. Quality Assurance

Inspecting parts on the shopfloor helps minimise the risk of producing defective products or product recalls, which can be costly and damaging to a manufacturer.

10. To Improve Safety:

Defects in parts can lead to safety hazards. By inspecting parts on the shopfloor, manufacturers can identify and correct defects before they cause accidents or injuries.